Table of Contents

To withstand complex environments, outdoor LED screens typically require unique technological processes to ensure their proper functioning. Currently, there are three main types of outdoor LED display technologies: DIP (Dual In-line Package), SMD (Surface Mounted Devices), and LOB (Lens on Board). Each has its own characteristics and application scenarios.

In this article, Chainzone will conduct a comparative analysis of DIP vs. SMD vs. LOB, introducing their principles, characteristics, and application fields. After reading, you will deepen your technical understanding of these three packaging technologies and thus make more rational purchasing decisions.

What is DIP LED Technology?

1. DIP LED Packaging Process

DIP LED technology, short for Dual In-line Package LED technology, involves encapsulating LED chips between two pins, typically in the form of individual LED lamp beads.

2. Structural Features

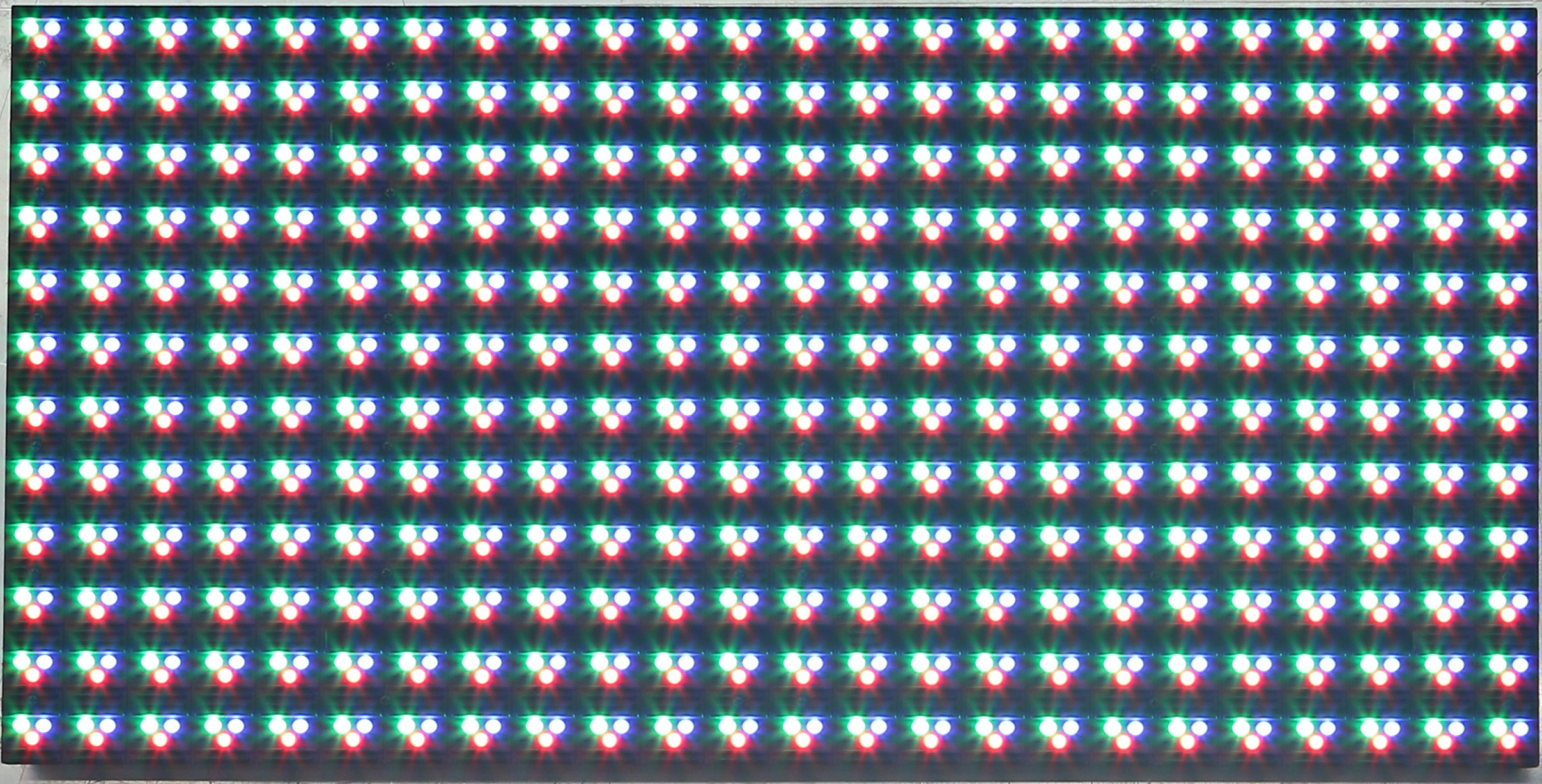

The DIP LED structure is relatively simple. The LED lamp bead is inserted directly into the PCB (Printed Circuit Board) via its pins and then fixed through soldering. DIP LEDs are typically cylindrical with a spherical top, which helps improve light projection. Each DIP LED can only produce a single color, so a combination of red, green, and blue LEDs is required to form a full-color display screen.

3. Characteristics of DIP LED Technology

- Long Pin Design: The pins of DIP lamp beads are arranged in two rows and are relatively long, allowing them to be directly inserted into the corresponding holes on the circuit board. The electrical connection is built through soldering, enabling flexible and convenient installation.

- Simple Packaging Structure: The packaging structure of DIP lamp beads is relatively simple, resulting in lower production costs.

- High Reliability: DIP packaging technology has been extensively validated in the market, ensuring high reliability.

4. Application of DIP LED Technology

Due to its simple structure and cost-effectiveness, DIP packaging technology was widely used in early applications and is suitable for outdoor large-pixel pitch displays. However, since the pixel pitch is limited by the lamp bead’s diameter, current applications are limited to P6 screens, and it is challenging to produce higher-density outdoor LED displays.

What is SMD LED Technology?

1. SMD LED Packaging Process

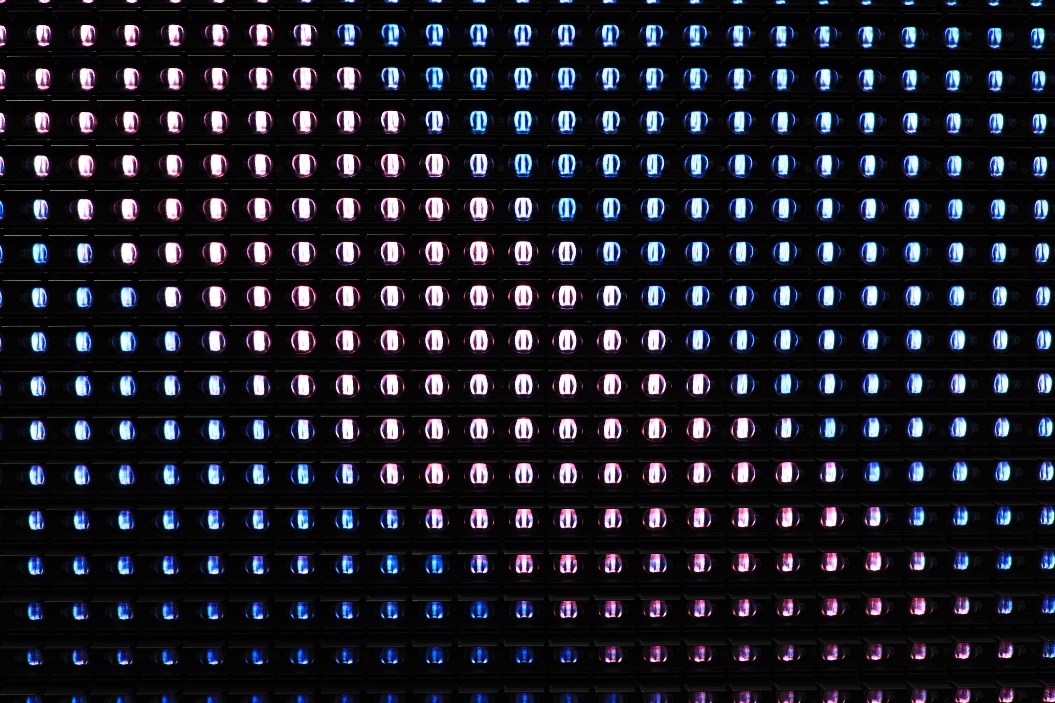

SMD LED packaging technology is widely used in LED display applications and stands for Surface Mounted Device. In LED displays, SMD packaging technology refers to encapsulating LED chips, brackets, leads, and other components into small, pinless LED lamp beads. These beads are then directly mounted on the printed circuit board (PCB) using automated surface mount machines.

2. Characteristics of SMD LED Technology

- High Integration and Miniaturization: SMD packaging technology results in small and lightweight LED components, making them suitable for high-density integration. This helps achieve smaller pixel pitches and higher resolutions, enhancing the smoothness and clarity of the display.

- Efficient Production: The use of automated surface mount machines significantly increases production efficiency, reduces labor costs, and shortens production cycles.

- Good Heat Dissipation: SMD-packaged LED components directly contact the PCB, facilitating heat dissipation and extending LED component lifespan.

- Easy Maintenance and Replacement: SMD components are mounted on the PCB making repair and replacement more convenient and faster. This reduces the maintenance and downtime costs of the display screen.

3. Application of SMD LED Technology

SMD packaging technology can be found extensively in LED display screens, especially in outdoor LED displays with pixel pitches ranging from P2 to P10.

What is LOB LED Technology?

1. LOB LED Packaging Process: The Innovator and Leader of the Future

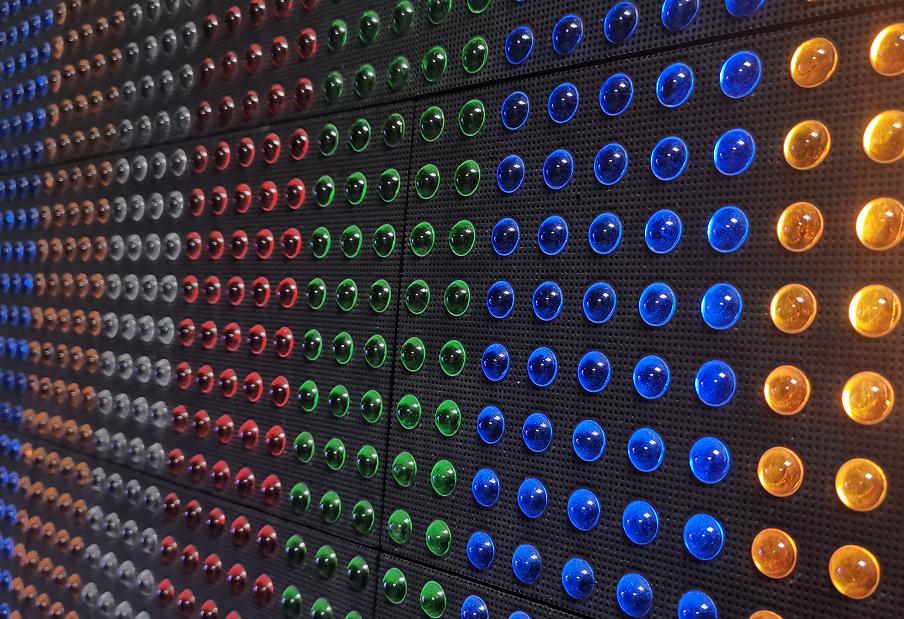

LOB technology (Lens On Board) is a rising technique in the outdoor LED display market. It gradually leads the way with innovative concepts of green energy-saving and efficient light control.

Specifically, LOB technology applies to outdoor LED displays. Its core principle is to install lenses made of high-molecular polymer materials above the lamp beads to change the light path and achieve a focusing effect. This design reduces unnecessary light loss and power consumption, enhancing light control and energy efficiency.

Close-up of the LOB LEDs in the V-Plus product series

2. Characteristics of LOB LED Technology

- Low Power Consumption and High Brightness: By installing lenses on the LED lamp beads, the focusing effect of the lenses concentrates the light, reducing light scattering and losses. This improves light efficiency and reduces power consumption. LED displays using LOB technology can save up to 80% energy compared to ordinary SMD outdoor display screens.

- High Contrast: LOB technology reduces sunlight reflection on the screen through optical lenses, enhancing the screen’s contrast. It provides a clear display even under midday sunlight, offering an excellent visual experience.

- Customizable Light Angle: LOB technology employs optical lens technology on the lamp board surface to achieve secondary light distribution by changing the light path of the LEDs. This design allows precise control of the LED light angle, projecting light into the effective viewing area.

- High Protection Performance: LOB technology provides multiple protections, including waterproofing, moisture resistance, impact resistance, dustproofing, corrosion resistance, salt resistance, and antistatic properties.

3. Application of LOB LED Technology

LOB LED packaging technology is primarily used in outdoor LED display screens, especially in outdoor advertising scenarios that require high protection performance. It achieves precise light control, energy efficiency, and enhanced safety. In the market for high-performance, green, and energy-saving outdoor display screens, LOB technology is leading the future development direction.

Summary

This article has explored three outdoor LED display technologies: DIP vs. SMD vs. LOB. Each has its advantages suitable for different applications.

DIP technology is ideal for large-pixel pitch, cost-effective outdoor display screens; SMD technology is widely used in high-resolution displays; and LOB technology, with its innovation and energy-saving features, represents a significant direction for the future outdoor LED display market.

When choosing an outdoor LED display, you should consider the technical characteristics, cost, and performance based on your own needs and application scenarios to make a wiser decision.

You can also contact Chainzone. As a professional LED screen manufacturer, we can provide you with purchasing advice that best fits your budget and actual needs for outdoor LED screens!