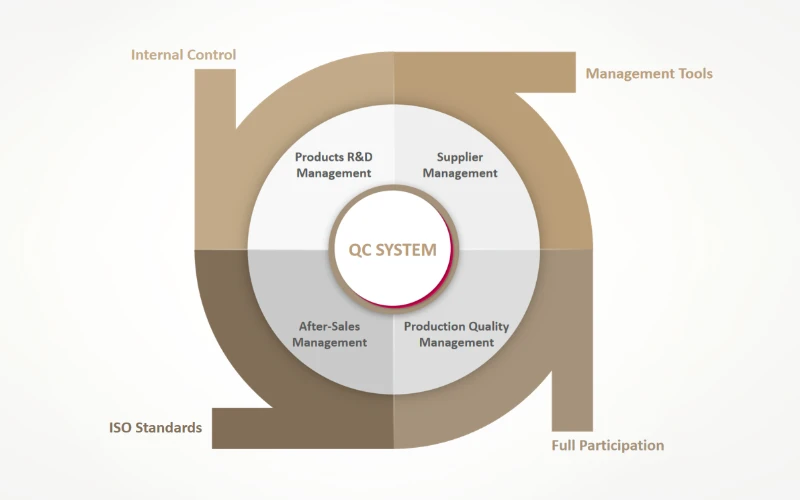

QUALITY CONTROL SYSTEM

Chainzone relies on a 1/4/4 quality control system and has a strict quality control process from product development to mass production, as well as subsequent local installation and maintenance. We strive to let our partners enjoy quality service.

DISCOVER OUR LABORATORY

Excellence, Truth, and Responsibility are the pillars of what we pursue. We subject the entire product system to rigorous environmental testing. Our engineers utilize this testing data to enhance and develop our full line of sign products in intelligent display and intelligent traffic, ensuring all are of best quality and reliability.

Optical Laboratory

It is used to measure the spatial light intensity distribution of LED products and various optical parameters. Including: spatial light intensity distribution curve, light intensity distribution curve on any cross-section, equal illuminance distribution curve, brightness limit curve, regional luminous flux, lamp efficiency, glare level, total luminous flux of lamps, effective luminous flux, utilization factor, etc.

Electrical Laboratory

It is used for routine project testing of raw materials and finished products. Including: various electrical parameters of components,

product power, withstand voltage, leakage current, grounding resistance, etc.

Measure whether raw materials and finished products meet expected usage and shipping standards, as well as electrical parameters (power, power factor,voltage, current), etc.

Environmental Laboratory

According to domestic and foreign standards, it can conduct environmental test, corrosion resistance test, simulated transportation test, vibration test, simulated solar radiation test, product tightness test, high and low temperature test, thermal shock test and other reliability tests. Covers most of the items of climate environmental test, mechanical environmental test and comprehensive environmental test. It can quickly find product defects and analyze the causes of defects to improve product quality.

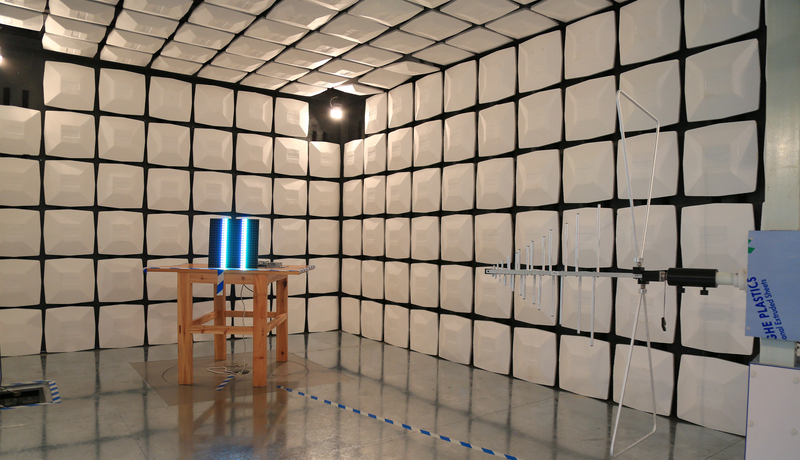

EMC Laboratory

The EMC laboratory is mainly used for interference testing (EMI) of products under development. The testing content includes space radiation interference testing and conducted interference testing. Analyze the source and path of interference through pre-tests to facilitate the identification and optimization of EMC problems.